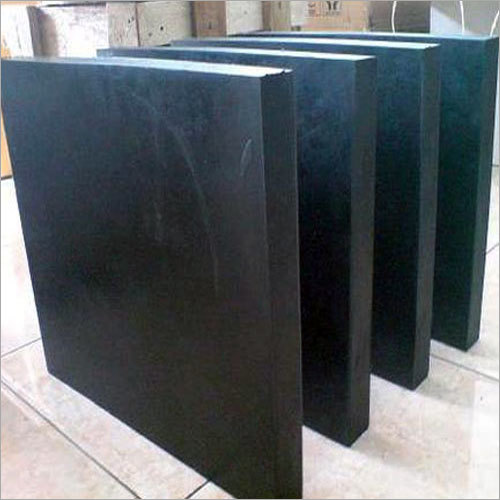

Neoprene Bridge Bearing

Product Details:

- Usage Bridge

- Material Other

- Size 18 x 18 inch

- Color Black

- Click to view more

Neoprene Bridge Bearing Price And Quantity

- 1 Piece

- 1800 INR/Piece

Neoprene Bridge Bearing Product Specifications

- Other

- Bridge

- Black

- 18 x 18 inch

Product Description

As efficient bearing for pre-cast, pre-stressed concrete or steel beams in bridge and buildings, Elastomeric Bearings manufactured by us permits a smooth and uniform transfer of load from the beam to the sub structure and allow beam rotation there at the bearing due to deflection of the beam under load. They further allow lateral and longitudinal movement of the beam caused by thermal forces. Have no moveable parts and thermal expansion and contraction are absorbed by the pad's ability to give and take in shear. There is no sliding motion between pad and beam or between pad and abutment.

MANUFACTURING PROCEDURE OF ELASTOMERIC BEARINGS

Elastomeric bearings shall be composed of multiple laminates of elastomeric material separated by steel reinforcing. The over all size of the bearings, the number of laminates and thickness of laminates are designed in accordance to the requirement of load to be transferred. Bearings having steel plates as reinforcement shall be cast/compression moulded/vulcanized as a single unit in a mould under pressure and heat.

Tests confirming to IRC83 Part II/UIC772.

In house Quick production test of all bearings are done at Clients/Representative presence. Tests confirming to IRC83 Part II/UIC772. Specification in accordance with acceptance testing on either Level I or Level II or short/Long- Duration Compression test up to 800Tons with horizontal shear upto 100 Tons can be carried out in our facility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free