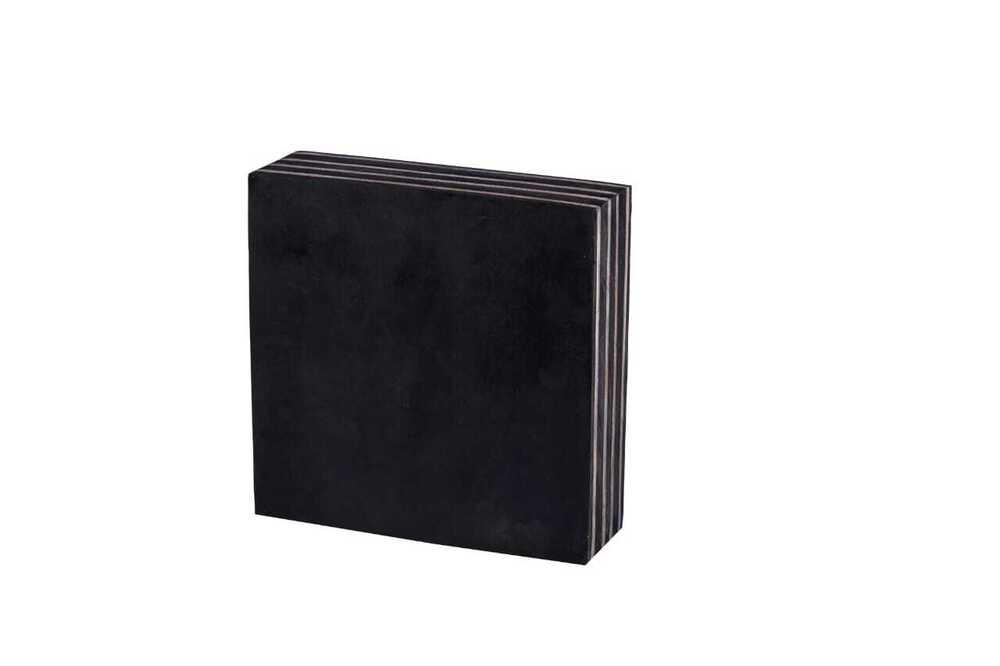

Elastomeric Bridge Bearing Pads

Product Details:

- Color Black

- Usage Bridge

- Size Customized

- Number Of Rows Single Row

- Warranty 1 Year

- Click to view more

Elastomeric Bridge Bearing Pads Price And Quantity

- 1 Piece

- 1800 INR/Square Centimeter

Elastomeric Bridge Bearing Pads Product Specifications

- 1 Year

- Bridge

- Single Row

- Black

- Customized

Elastomeric Bridge Bearing Pads Trade Information

- Per Day

- Days

Product Description

We are one of the eminent manufacturers and suppliers of Elastomeric Bridge Bearing Pads. These pads are manufactured using the finest quality material, procured from reliable vendors under the observation of seasoned professionals. Offered pads are checked at our well equipped facility on various parameters to ensure its long service life. These pads provide economical solution used to withstand loads and deformation in any direction for the construction of large span bridges and buildings. Elastomeric Bridge Bearing Pads are available at industry leading prices.

Application:

Laminated elastomeric bearing or neoprene bridge bearing pads are simple to introduce as contrasted with different sorts of bearings deployed and demanded zero handling. Dissimilar to numerous elastomer, neoprene rubber that experiences no mark contraction at least temperature when bridge neck thermal contraction is performed at optimum as such contraction can be harmful to structure and bearing. Suitably compounded and precisely outlined bearings can be anticipated to work productively for minimum 15 years.

As utilitarian bearings for sell beams, pre-stressed concrete or pre-cast concrete in buildings and bridge is imperative, our elastomeric bridge bearings allow uniform and smooth transfer to load through beam to the frame as well as permit beam revolution for bearings because of beam deflection under load. These also permit longitudinal and lateral beam movement that is induced by heat pressures. They do not possess any movable components. In addition, thermal contraction and expansion are assimilated by ability of pad to offer and take shear. No sliding movement between pad and abutment or between pad and beam is present.

Benefits:

Our bridge bearings are composed of numerous elastomeric material laminates that is separated through steel supports. The complete bearings size and laminates thickness are intended as per demand of transferred load. Bearings possessing steel plates are supported should be compresses or cast vulcanizes or molded as one unit in mold below heat and pressure.

Testing Of Our Bearings:

In house rapid manufacturing test of every bearing is completed at representative or clients presence. Trails adhering to IRC 83 part 2/UIC773. Particulars as per affirmed examination on either level 2 or level 1 or long and short durations compression trails of approximately 800 ton with leveled shear of around 100 tons mat be operated in our amenity.

Specification

|

Shape |

Customized |

|

Size |

Customized |

|

Material |

Polychloropene |

|

Dimension |

Customized |

|

Color |

Black |

Call Me Free

Call Me Free